ACM

FEP/PFA

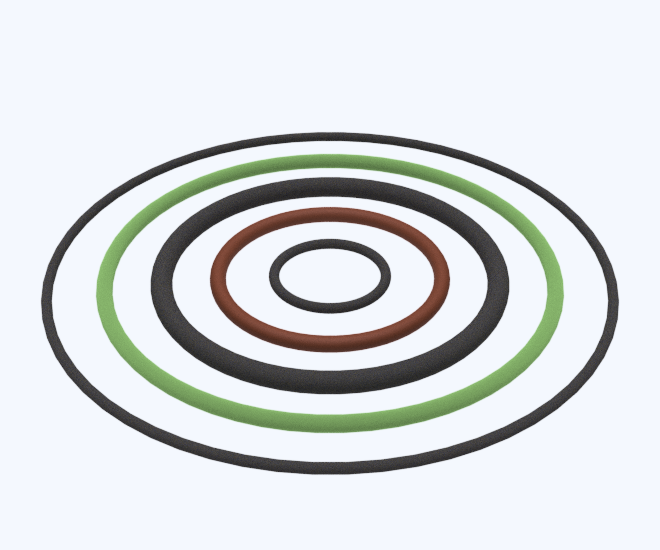

O-rings

Materials

Imperial O-ring sizes

BS1806 - AS568A

1/8” Cross section (3.53mm c/s)

Metric O-ring sizes

1/4” Cross section (6.99mm c/s)

O-rings are simple, yet vital components in various mechanical systems. They are torus-shaped seals, typically made from elastomeric materials like rubber, silicone, or fluorocarbon, but can also be produced from other materials like metal or thermoplastics. O-rings are used to create a tight seal between two or more parts, preventing the escape or ingress of fluids or gases.

The basic design of an O-ring involves a circular cross-section, which fits into a groove and is compressed between two surfaces during assembly. This compression creates a seal that can withstand various pressures, temperatures, and chemical exposures, making O-rings extremely versatile.

Benefits

Simplicity and Cost-Effectiveness:

- Design and Manufacture: O-rings have a straightforward design, making them easy and cost-effective to produce. This simplicity also translates into ease of installation and replacement.

- Low Cost: Due to their basic shape and material efficiency, O-rings are generally inexpensive compared to other sealing methods.

Versatility:

- Wide Range of Applications: O-rings are used in diverse industries, including automotive, aerospace, plumbing, medical devices, and many types of machinery. They can function in static applications (where there is no movement between the sealed parts) or dynamic applications (where parts are in motion relative to each other).

- Material Flexibility: They can be made from a variety of materials, each tailored for specific operating conditions such as high temperatures, chemical resistance, or extreme pressures.

Effective Sealing:

- High-Pressure Resistance: O-rings are capable of withstanding high pressures, making them suitable for hydraulic and pneumatic systems.

- Leak Prevention: Their ability to maintain a reliable seal prevents leaks, which is crucial for maintaining system integrity and efficiency.

- Self-Reinforcing Seal: Under pressure, O-rings expand to fill gaps and enhance the sealing effect, which further improves their performance.

Durability:

- Long Service Life: When made from appropriate materials for the specific application, O-rings can last a long time, providing consistent performance and reducing the need for frequent replacements.

- Resistance to Wear and Tear: Many O-ring materials are designed to resist abrasion, compression set, and other forms of mechanical wear.

- Temperature Variability:O-rings can be formulated to withstand a wide range of temperatures, from extreme cold to high heat, without losing their sealing properties.

- Chemical Compatibility:Specialized O-rings can resist aggressive chemicals, oils, and gases, making them suitable for use in chemical processing plants, fuel systems, and more.

- Simple Installation: Installing an O-ring usually requires no special tools or techniques, and they can be easily replaced during routine maintenance.

- Minimal Maintenance: Due to their robustness and durability, O-rings typically require minimal maintenance once installed.