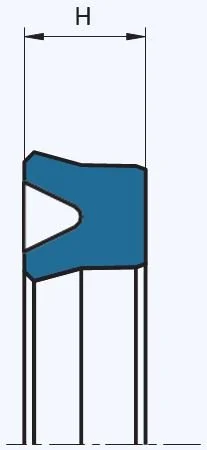

RS106

Symmetrical Rod Seal

For simple applications and universal use.

Not recommended for new designs.

Asymmetrical profiles like RS101 are preferable.

Material and Application Parameters

| Sealing Element | Temperature (°C) | Max. Sliding Speed (m/s) | Maximum Pressure² | ||

|---|---|---|---|---|---|

| HPU Premium | -30 | - | +110 | 0.5 | 400 bar (5800psi) |

| HPU Diet | -20 | - | +110 | 0.5 | 400 bar (5800psi) |

| SLPU | -20 | - | +110 | 0.7 | 400 bar (5800psi) |

| HPU Low Temperature | -50 | - | +110 | 0.5 | 400 bar (5800psi) |

| NBR Standard | -30 | - | +100 | 0.5 | 160 bar (2300psi) |

| FPM Diet | -20 | - | +200 | 0.5 | 160 bar (2300psi) |

| EPDM Spring | -50 | - | +150 | 0.5 | 160 bar (2300psi) |

| HNBR Diet | -25 | - | +150 | 0.5 | 160 bar (2300psi) |

| MVQ Diet | -60 | - | +200 | - | - |

| Aflas Standard | -10 | - | +200 | 0.5 | 160 bar (2300psi) |

Standard Dimensions

| Maximum radial extrusion gap s¹ (mm) | |||||||||||

| P² | R² | P² | R² | ||||||||

| Ød f8 (mm) | ØD H10 (mm) | L +0.2mm | H (mm) | C (mm) | 20 bar | 100 bar | 250³ bar | 400 bar | 700 bar | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ≥6 - ≤25 | d + 8 | 6.30 | 6.10 | 3.50 | 0.33 | 0.23 | 0.17 | 0.16 | 0.14 | 0.11 | 0.05 |

| ≥25 - ≤50 | d + 10 | 8.00 | 7.80 | 4.00 | 0.37 | 0.26 | 0.22 | 0.16 | 0.17 | 0.16 | 0.10 |

| ≥50 - ≤150 | d + 15 | 10.00 | 9.70 | 5.00 | 0.46 | 0.31 | 0.31 | 0.24 | 0.22 | 0.25 | 0.19 |

| ≥150 - ≤300 | d + 20 | 14.00 | 13.60 | 6.00 | 0.54 | 0.34 | 0.39 | 0.27 | 0.25 | 0.32 | 0.26 |

| ≥300 - ≤500 | d + 25 | 17.00 | 16.50 | 8.50 | 0.61 | 0.37 | 0.46 | 0.30 | 0.29 | 0.39 | 0.33 |

| ≥500 - ≤700 | d + 30 | 25.00 | 24.30 | 10.00 | 0.67 | 0.40 | 0.52 | 0.34 | 0.32 | 0.45 | 0.39 |

| ≥700 - | d + 40 | 32.00 | 31.20 | 13.00 | 0.67 | 0.40 | 0.52 | 0.40 | 0.32 | 0.45 | 0.39 |

| Rod Seal, Single Acting, Hydraulics |

|---|

The dimensions s + c are dependent on the respective seal type.

Brightened symbols: seal only for limited use.

Please contact us

| Design | Application |

|---|

Surface Finish

| Roughness | Rtmax(µm) | Ra(µm) | Material Portion |

|---|---|---|---|

| Sliding Surface | ≤ 2.5 | 0.1 - 0.5 | Ratio contact area: 50 - 95% at a cutting depth of 0.5 x RZ starting from cref = 0% |

| Groove Base | ≤ 6.3 | ≤ 1.6 | |

| Groove Flanks | ≤ 15 | ≤ 3 |